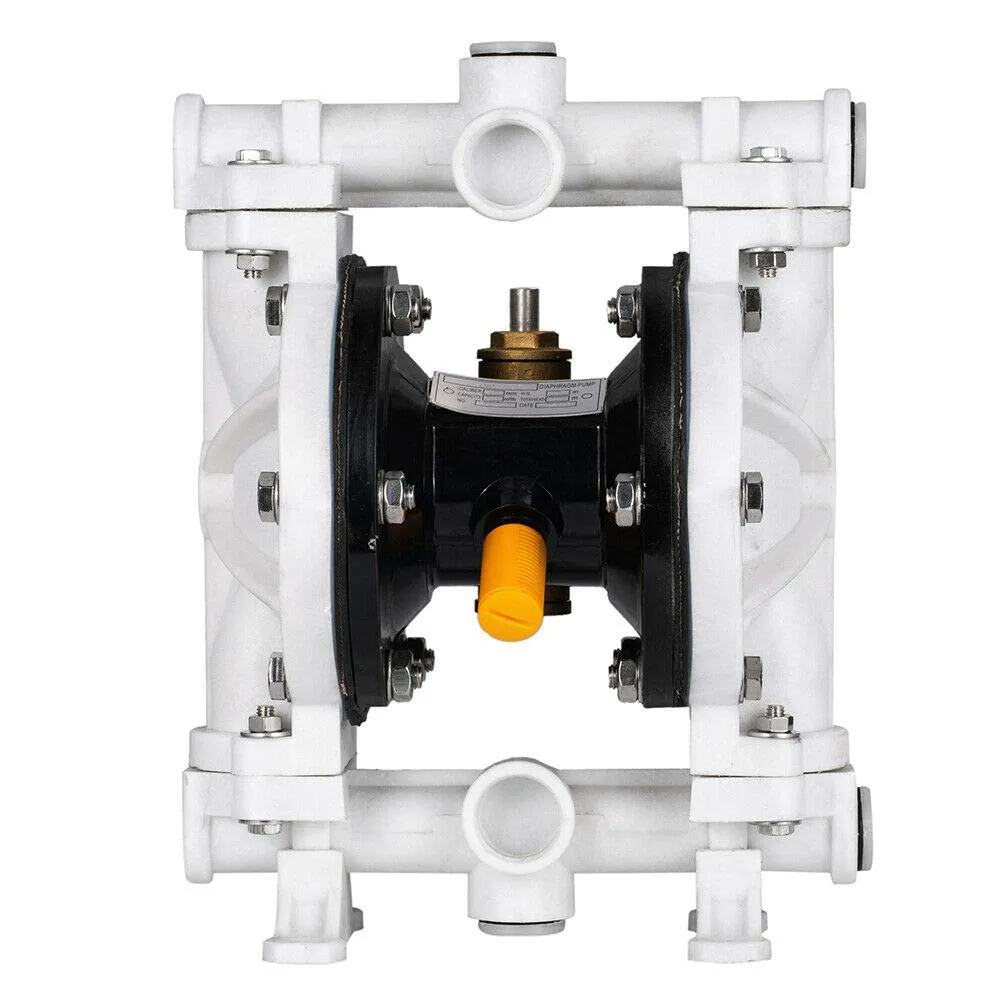

The Air Operated Double Diaphragm Pump is an essential tool for any industrial setting that requires efficient and reliable fluid transfer. Specifically designed for waste oil, diesel, grease, and kerosene, this pump features a durable construction with a polypropylene body and PTFE diaphragms, ensuring longevity and reliable performance.

One of the standout attributes of this pump is its working principle. The pump contains two symmetrical working chambers, each equipped with a diaphragm. The central link integrates these chambers into one functional unit. When compressed air enters the pump inlet, it flows through the valve body, introducing air into one of the chambers. This action promotes the movement of the diaphragm, while the other chamber expels gas. Once the stroke is complete, the gas distribution mechanism automatically directs compressed air into the opposite chamber, causing the diaphragms to operate in unison.

Versatility is a key feature of this diaphragm pump. It can handle a wide range of fluids, including waste oil, alcohol, hydraulic oil, gasoline, diesel, detergents, beverages, and more. As a result, it finds applications across various industries, including petroleum, metallurgy, mining, coatings, printing, water treatment, and automotive sectors. Moreover, the pump provides multiple porting options to accommodate different application needs.

| Specifications | Details |

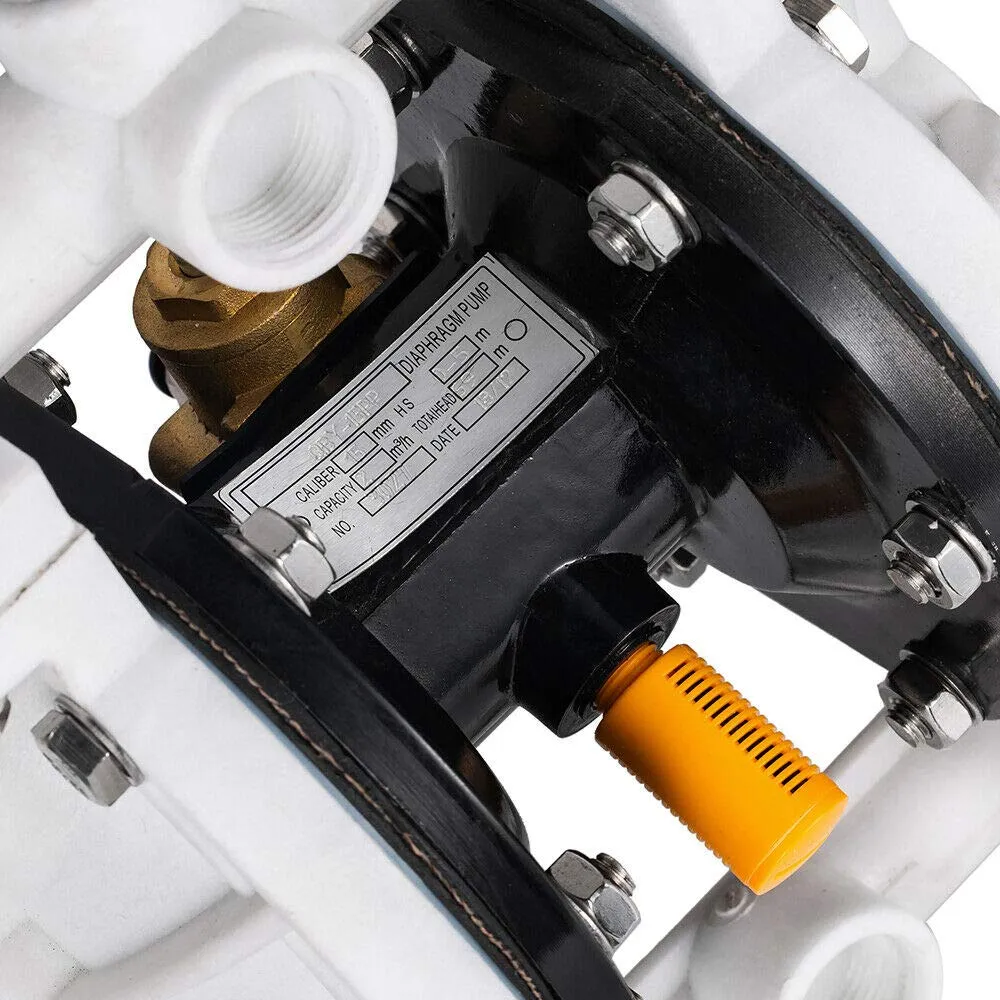

| Model | QBY-15PP |

| Body Material | Polypropylene |

| Max Flow Rate | 2 m³/h (13 GPM) |

| Max PSI | 100 psi |

| Operating Temperature | -20℉ ~ 150℉ |

| Max Head | 69 m (226.4 ft) |

| Self-Priming Dry | 3 m (10 ft) |

| Self-Priming Wet | 4.6 m (15 ft) |

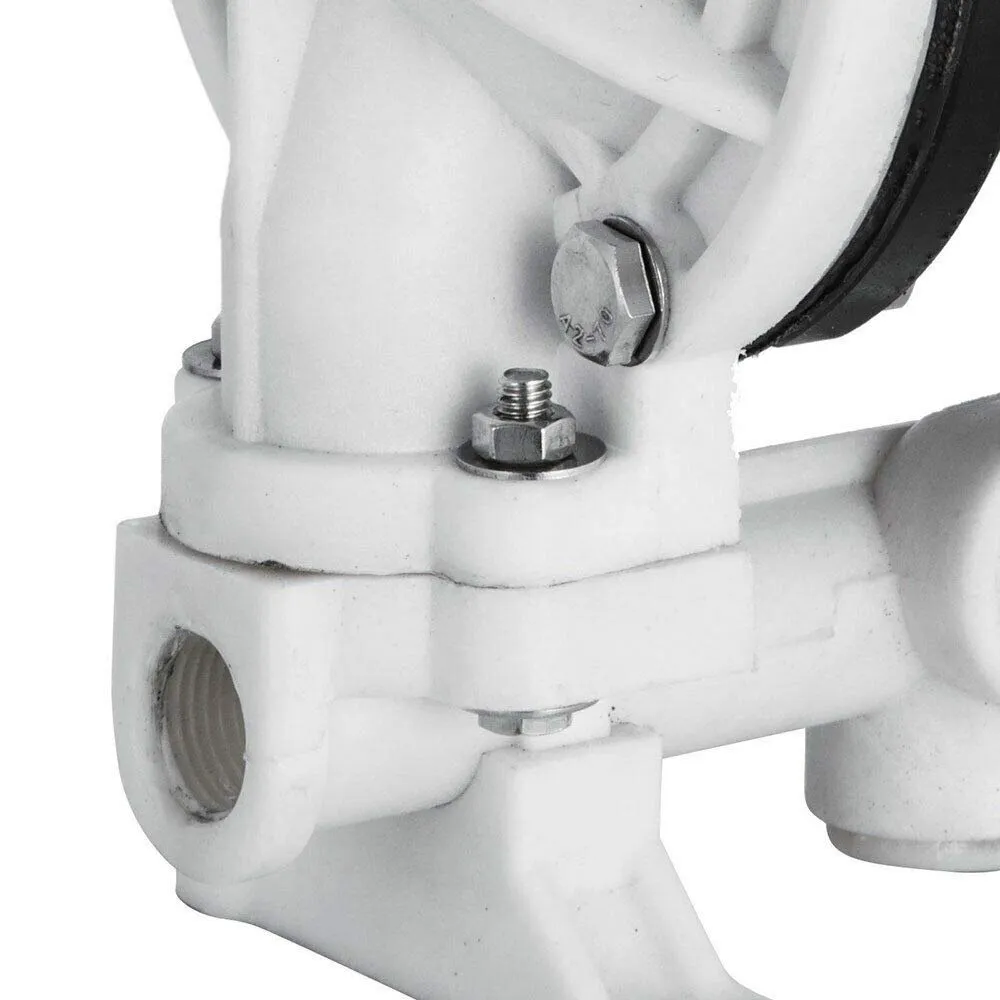

This air-operated double diaphragm pump features a 1/2 inch inlet and outlet and a 1/4 inch air inlet, making it suitable for a variety of fluid transfer applications. Its design allows for the handling of suspended solids up to 3/32 inches in diameter, ensuring good abrasion and chemical resistance. The solid construction offers serviceability and is environmentally sound, promoting leak-free fluid handling.

In terms of performance, the pump operates efficiently under varying conditions. With a suction capability of 0-5 m (0-16.4 ft) and a maximum lift of 69 m, it is an ideal choice for low viscosity petroleum fluids and other applications requiring reliable fluid transfer. The bolted construction ensures that it remains leak-proof, while the unbalanced air valve guarantees no-stall operation.

For anyone looking for a dependable solution for fluid transfer, the Air Operated Double Diaphragm Pump is an excellent choice. With a two-year warranty, you can trust this product to deliver high performance and reliability in your industrial applications.

Reviews

There are no reviews yet.