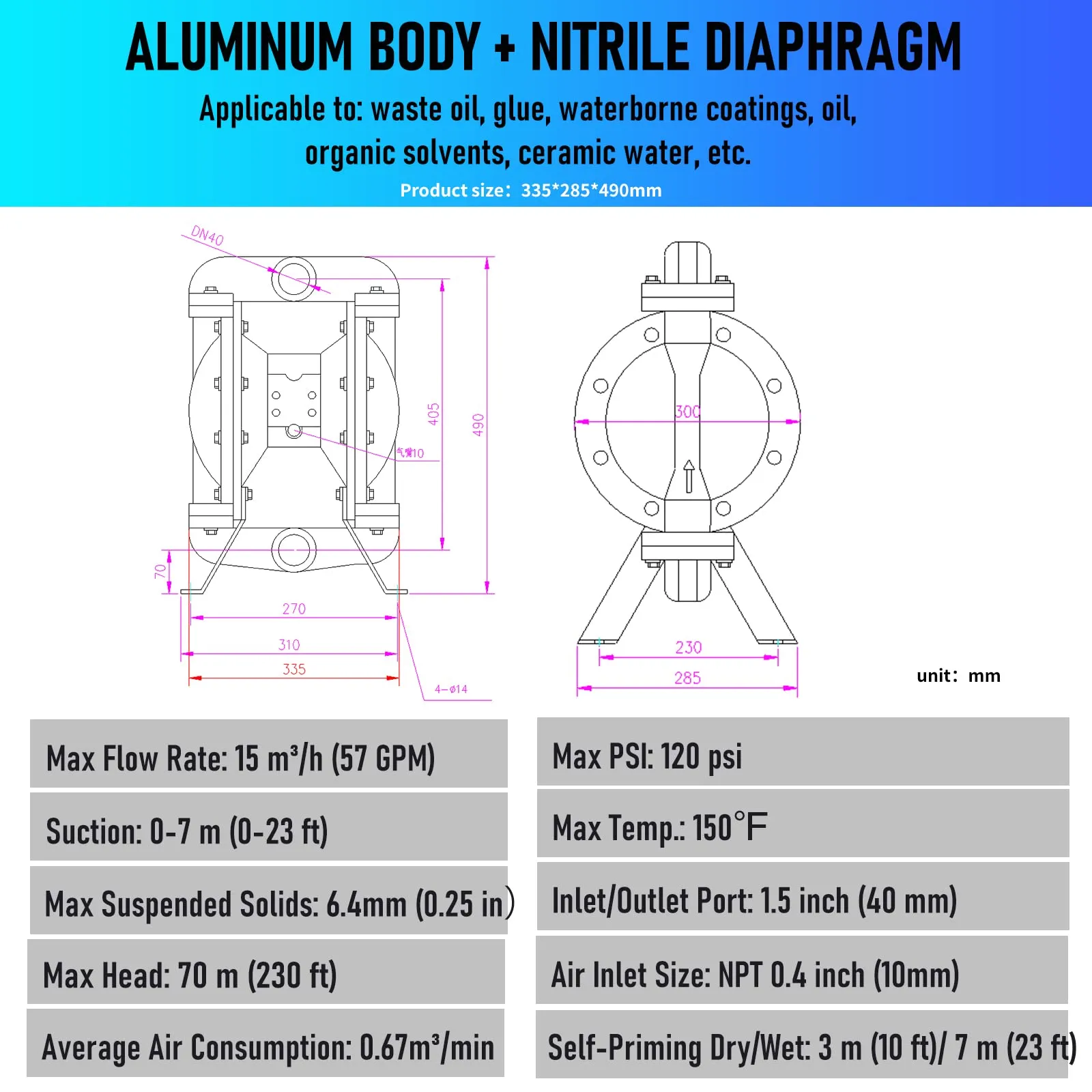

Introducing the Pneumatic Double Diaphragm Pump, a remarkable solution for fluid and viscous liquid delivery. This pump features a 1.5-inch inlet and outlet and boasts an impressive flow rate of 57 gallons per minute (GPM). Crafted from durable aluminum alloy, this pump is engineered to handle a variety of applications, particularly in chemical and industrial settings. With a maximum pressure capacity of up to 120 PSI, it is designed to efficiently transfer a wide range of liquids, including waste oil, ethanol, gasoline, engine oil, diesel oil, and more.

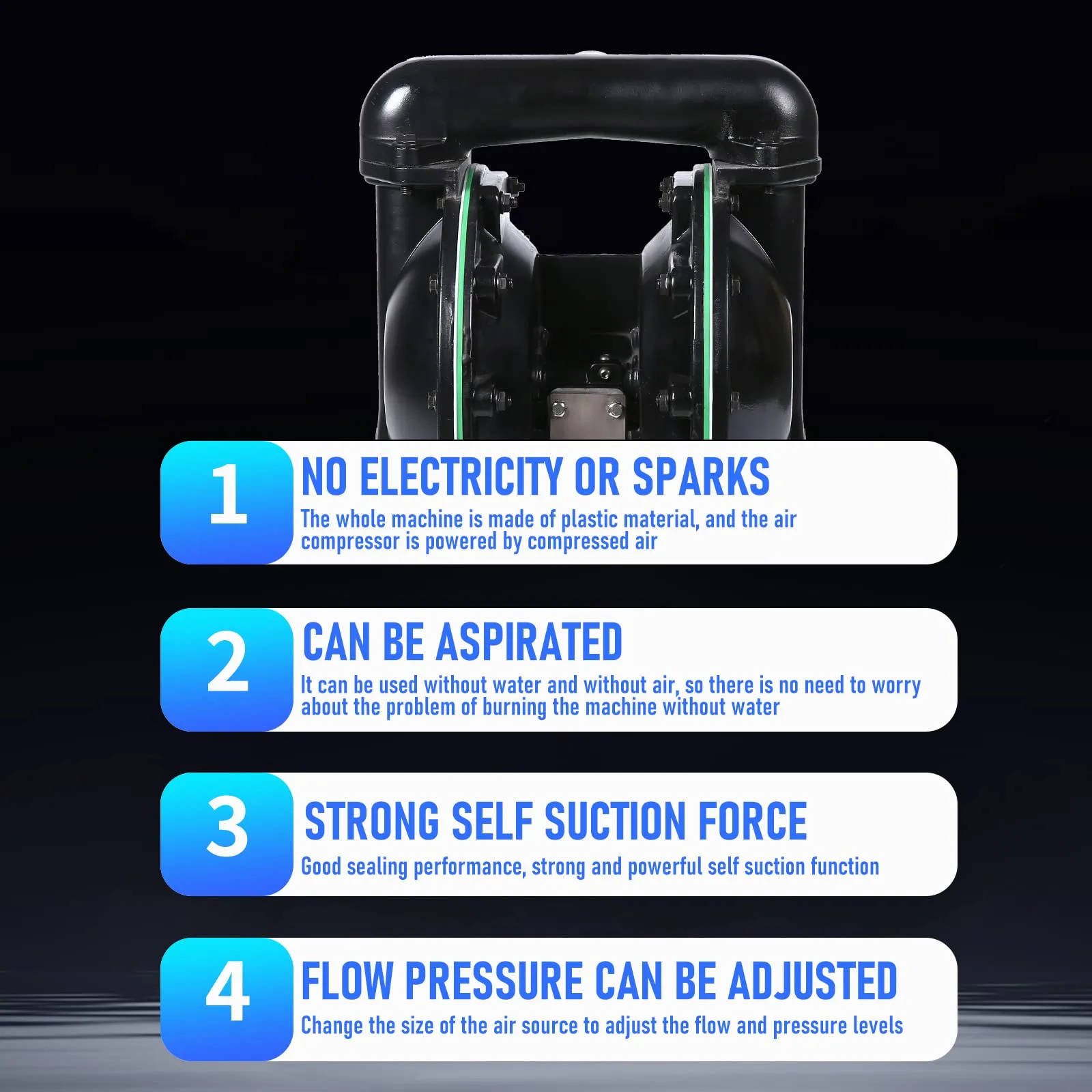

The versatile design of this pump allows for the conveying of both high-viscosity and low-viscosity liquids, making it suitable for industries such as petroleum, metallurgy, mining, paint, printing, water treatment, and automotive sectors. One of the standout features of this pump is its ability to operate without lubrication, ensuring that the medium and pump parts are completely separated. This design significantly reduces the risk of leakage, making it an excellent choice for transferring toxic or corrosive fluids.

| Applications | Fluid delivery, viscous liquids, waste oil, ethanol, gasoline, engine oil, diesel oil, mud, lime slurry, sewage, cement, antifreeze, industrial coatings, and more. |

| Main Features | No lubrication required, low energy consumption, modular design, low maintenance costs, and long lifespan. |

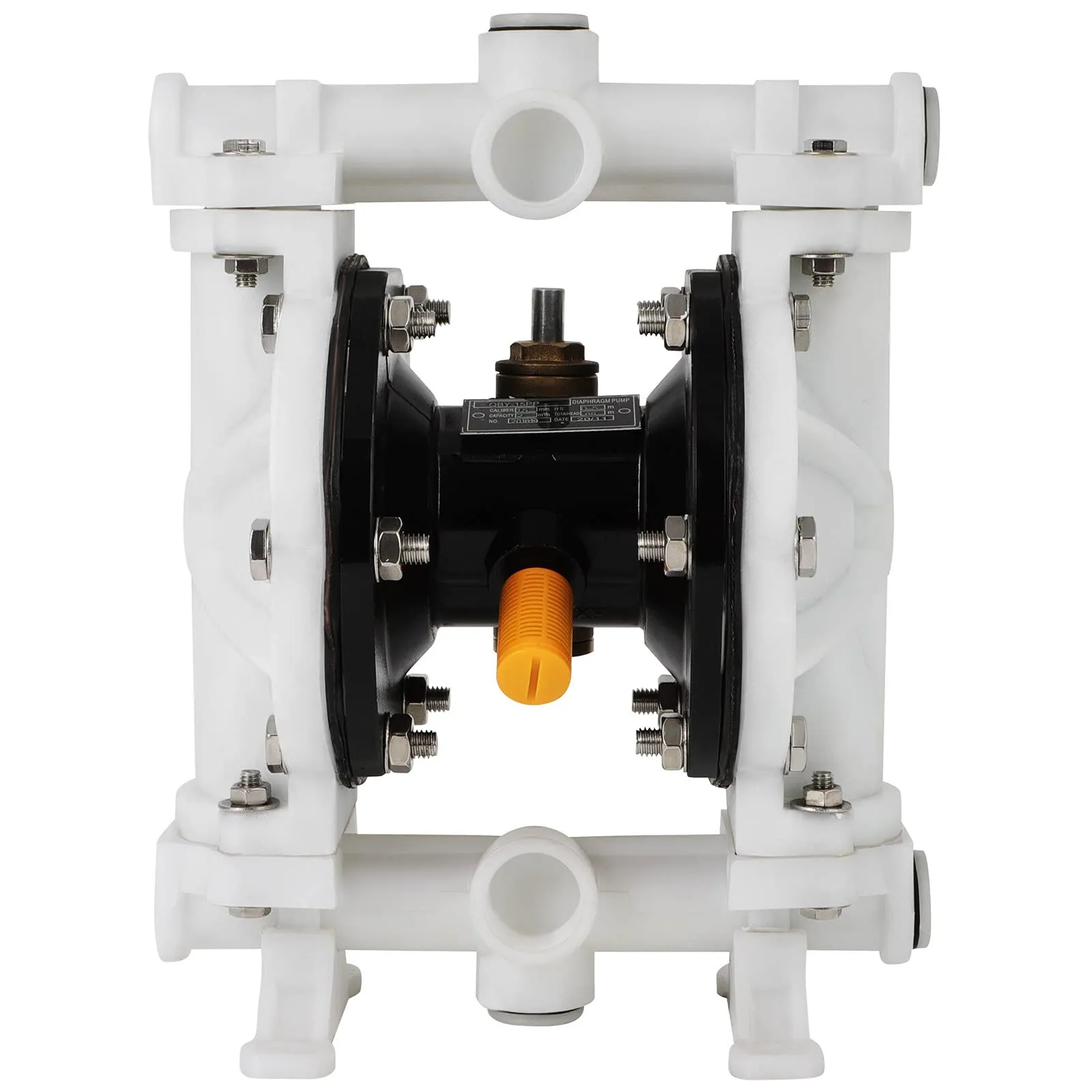

The pump operates using compressed air, which powers the diaphragm installed in two symmetrical chambers within the pump. The central connecting rod integrates these chambers, allowing for smooth operation. Compressed air enters the valve through the pump’s inlet and directs the flow into one chamber, facilitating diaphragm movement. Simultaneously, air is expelled from the opposite chamber, ensuring continuous operation.

In terms of materials, the aluminum alloy construction is ideal for mildly corrosive liquids, including glue, water-based coatings, and organic solvents. For more aggressive environments, other material options are available. Stainless steel is suitable for medium corrosive liquids such as solvents and pharmaceuticals, while polypropylene plastic can handle bleach and strong acids. Polyvinylidene fluoride offers high corrosion resistance for harsh chemicals like hydrochloric acid and sulfuric acid.

Installation of the Pneumatic Double Diaphragm Pump is straightforward. It is recommended to place the pump as close to the liquid source as possible. This minimizes the length of the intake pipe and reduces the number of connections, which can help maintain optimal performance. It is also advisable to use soft, flexible connections to minimize vibrations during operation.

Experience the efficiency and reliability of the Pneumatic Double Diaphragm Pump. Its robust design, coupled with its ability to handle various fluids, makes it an essential tool for a range of industries, ensuring that your fluid transfer needs are met with ease and precision.

Reviews

There are no reviews yet.