Introducing the High Precision Polyurethane Mixing System, a revolutionary solution designed specifically for the demanding needs of industrial applications requiring accurate chemical dosing. This state-of-the-art epoxy gear metering pump is engineered to handle high viscosity fluids with exceptional precision, ensuring optimal performance in various operational settings.

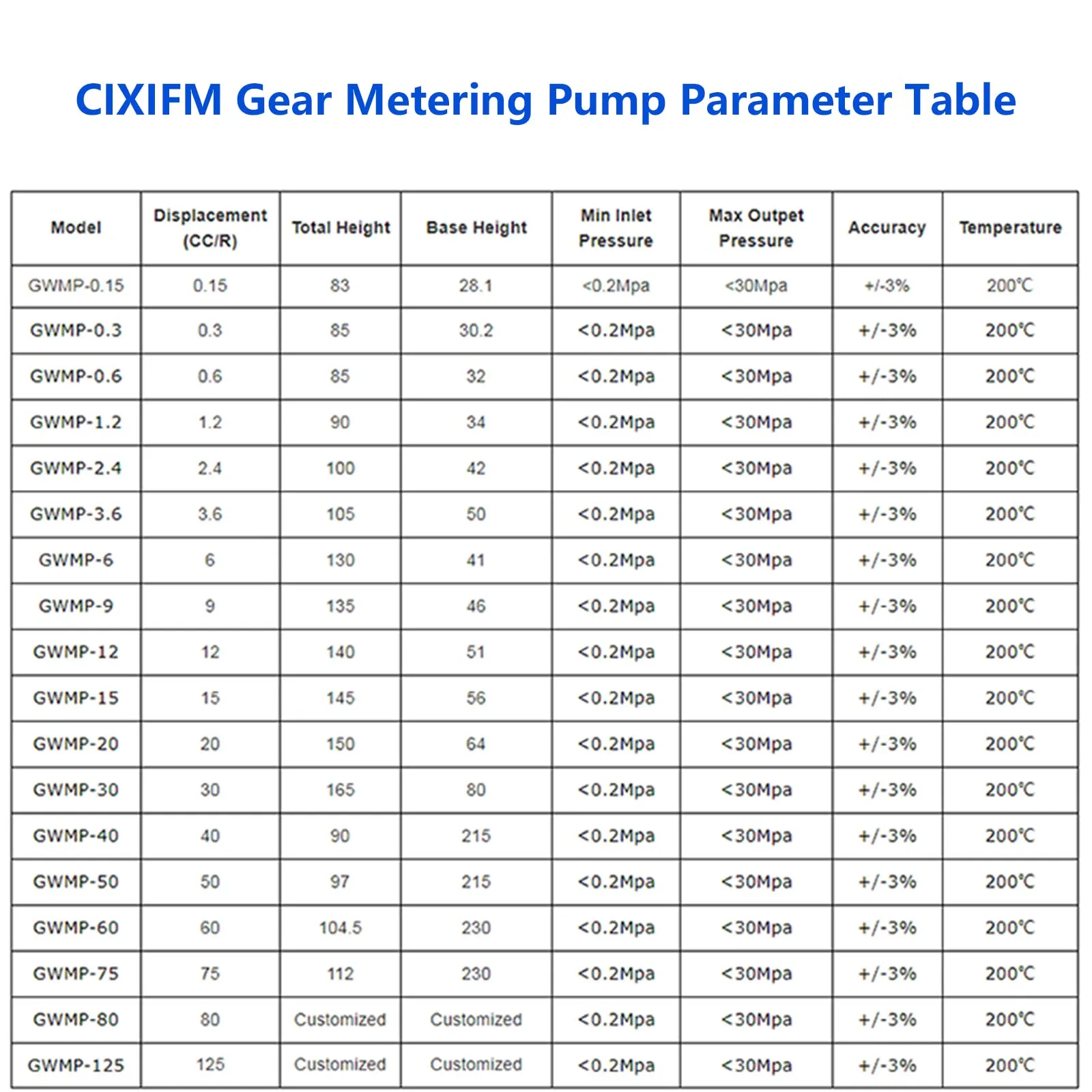

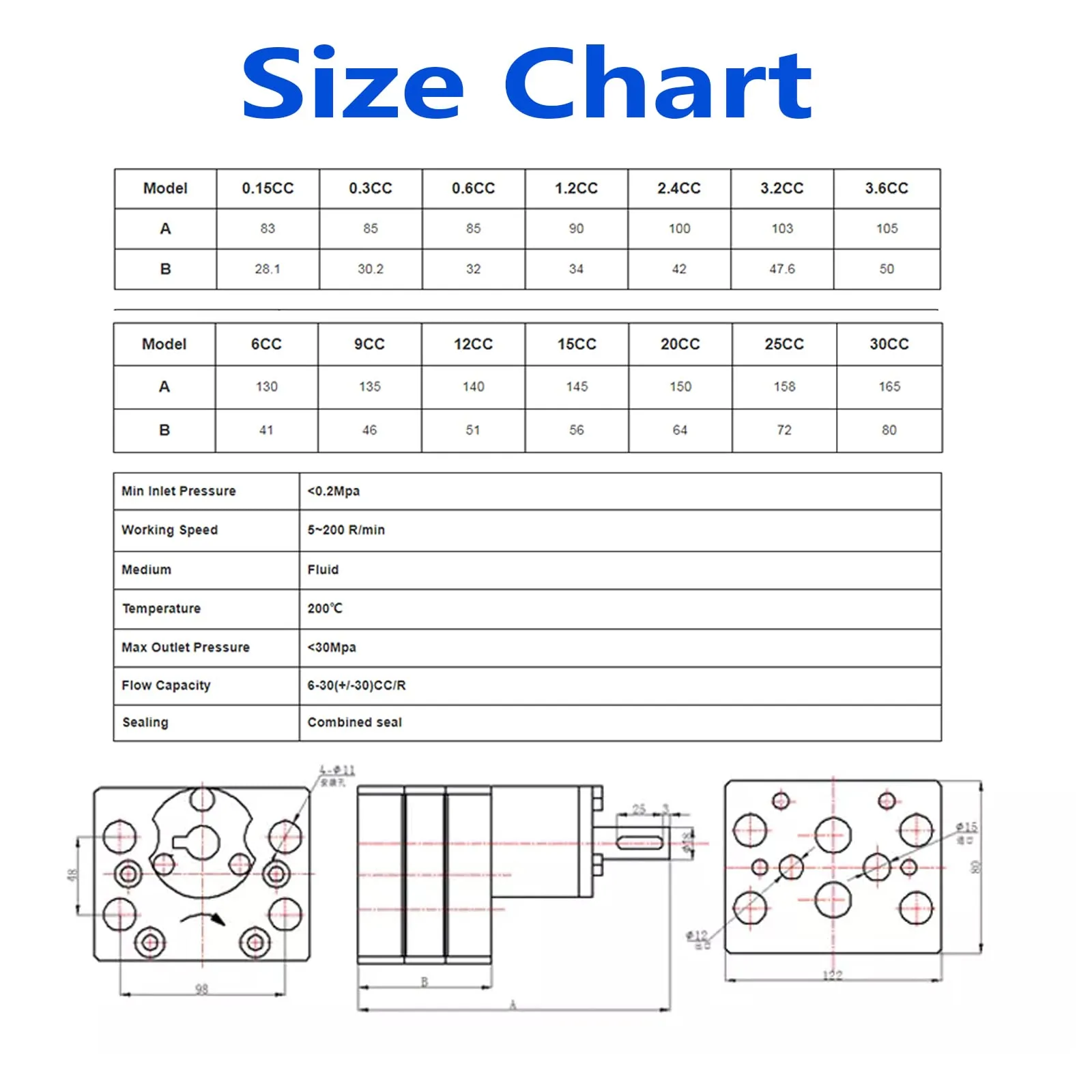

One of the standout features of this metering pump is its impressive displacement range, which spans from 0.15CC/R (±0.3%) to 60CC/R (±0.3%). This versatility allows it to cater to a wide array of fluids, making it an ideal choice for manufacturers and service providers looking for reliable equipment to facilitate their production processes.

In addition to its adjustable displacement, the High Precision Polyurethane Mixing System boasts a maximum outlet pressure of less than 8Mpa and can operate under a minimum pressure of less than 0.2Mpa. This capability ensures that the pump can efficiently handle the requirements of high-viscosity materials, which often necessitate higher pressures for effective dosing.

The working temperature range of this pump is equally impressive, accommodating both low and high thermal conditions. It can function effectively between 0°C to 180°C, and even up to 350°C for specific applications. This feature makes it suitable for a diverse range of chemicals and fluids, from those requiring low-temperature handling to those needing high-temperature operations.

To optimize the longevity and performance of your metering pump, it is crucial to adhere to specific operational guidelines, particularly when dealing with fluids of varying viscosities. For high-viscosity fluids (20000 to 100000 CPS), it is recommended to maintain a rotation speed of between 10 to 20 rpm. For medium-viscosity liquids (3000 to 20000 CPS), a rotation speed of 10 to 40 rpm is ideal. Finally, for low-viscosity liquids (20 to 3000 CPS), you can safely operate at speeds of up to 80 rpm, although speeds of 10 to 60 rpm are typically recommended for optimal performance.

When selecting a metering pump, especially for high-viscosity applications, consider opting for models with larger displacements. This approach ensures that you can achieve the necessary flow rates without compromising the integrity of the fluid being measured. If you are uncertain about the best model for your specific needs, we highly recommend reaching out to our customer service team for expert guidance.

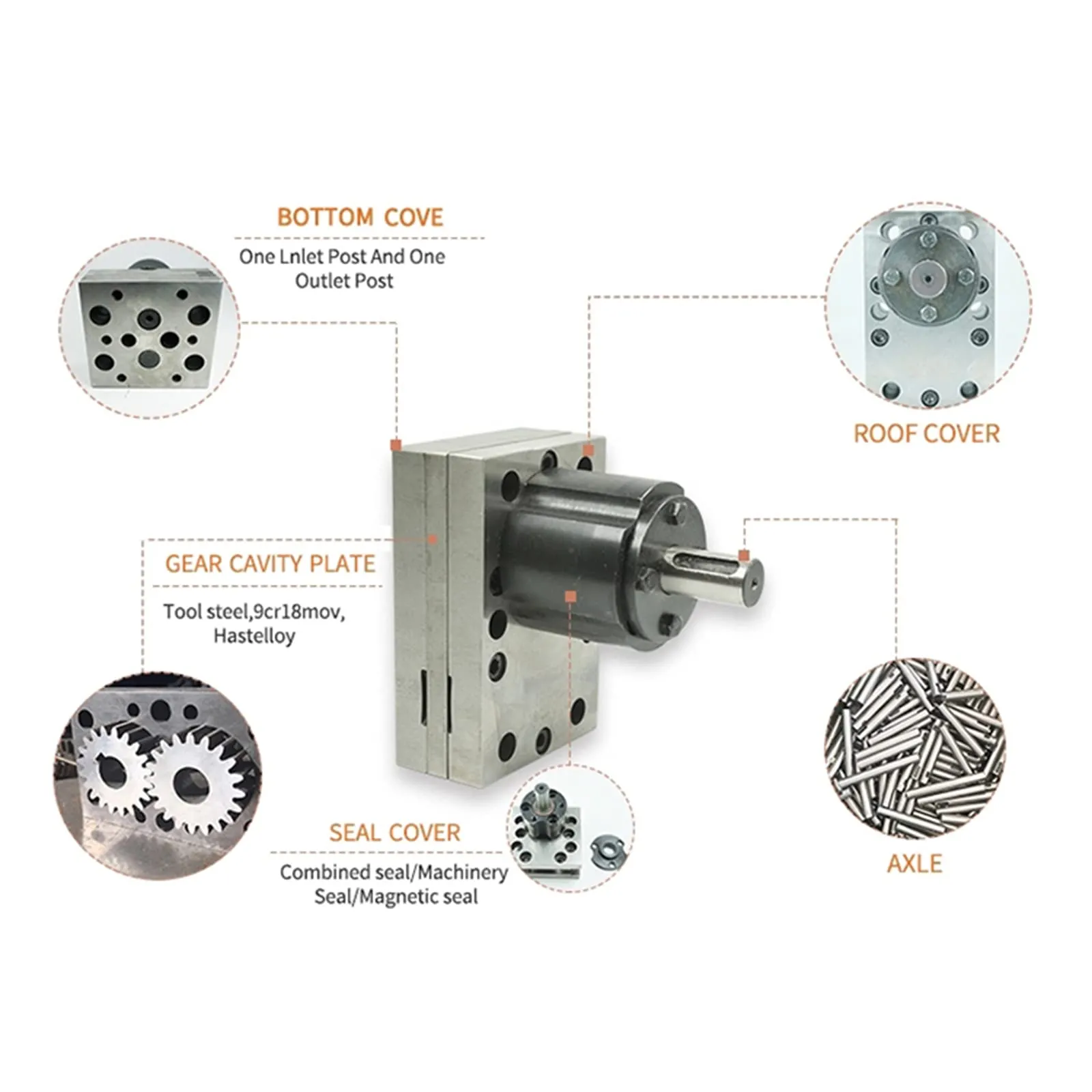

We pride ourselves on offering factory direct prices without compromising on quality. Our pumps are crafted with fine workmanship and exquisite measurement capabilities, ensuring that you receive a product that meets the highest standards of performance and reliability. Moreover, our after-sales customer service is dedicated to providing you with the support you need, ensuring that your investment is safeguarded and operational efficiency is maintained.

In summary, the High Precision Polyurethane Mixing System is the ultimate choice for those requiring a robust and precise chemical dosing solution. With its advanced features, unmatched versatility, and commitment to quality, this metering pump is designed to exceed your expectations and meet the rigorous demands of modern industrial applications.

| Brand: | CIXIFM |

| Displacement: | 0.15CC/R (±0.3%) ~ 60CC/R (±0.3%) |

| Medium: | Fluid |

| Minimum Pressure: | < 0.2Mpa |

| Maximum Outlet Pressure: | < 8Mpa |

| Working Temperature: | 0~180℃ or 180℃~350℃ |

| Direction of Rotation: | Clockwise from the direction of the rotation axis |

Reviews

There are no reviews yet.